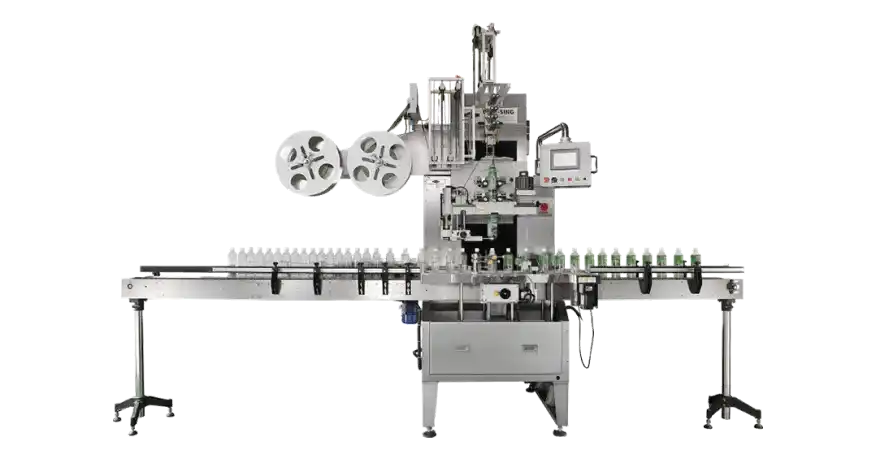

The global Sleeving Machine Market size is predicted to reach USD 3.88 billion by 2030 with a CAGR of 3.5% from 2025 to 2030. The sleeving machine market, critical for packaging solutions across industries like food and beverage, pharmaceuticals, and cosmetics, is experiencing significant growth in 2025. These machines, which apply shrink or stretch sleeves to containers for labeling and branding, are benefiting from technological innovations, sustainability trends, and rising demand for efficient packaging. This article explores the latest developments shaping the sleeving machine market, drawing on recent industry updates.

Surge in Demand for Sustainable Packaging

The global push for sustainability is a major driver of the sleeving machine market in 2025. Consumers and regulators are increasingly demanding eco-friendly packaging solutions, prompting manufacturers to develop machines compatible with recyclable and biodegradable materials. Recent reports highlight the growing adoption of stretch sleeve and shrink sleeve labels in the food and beverage sector, where they enhance product visibility while meeting environmental standards. This trend aligns with broader market shifts toward sustainable practices, encouraging companies to invest in sleeving machines that support green packaging initiatives.

Manufacturers are responding by designing machines that minimize material waste and energy consumption. For instance, advanced sleeving systems now feature precise cutting and application mechanisms, reducing excess sleeve material. These innovations not only lower environmental impact but also appeal to brands seeking to enhance their sustainability credentials, driving demand across industries.

Technological Innovations in Sleeving Machines

Technological advancements are at the forefront of the sleeving machine market’s growth. In 2025, manufacturers are integrating automation, artificial intelligence (AI), and digital twin technologies to enhance machine efficiency and precision. Automated sleeving machines with AI-driven controls can adjust sleeve application in real-time, ensuring consistent quality and reducing downtime. Digital twin simulations, which create virtual models of machines, allow manufacturers to optimize performance and predict maintenance needs, minimizing disruptions in high-speed production lines.

A notable example is the introduction of multi-axis control systems, which enable sleeving machines to handle complex container shapes and sizes. These systems, showcased at industry events like IMTEX 2025, improve throughput and adaptability, catering to diverse packaging needs. Additionally, smart connectivity features allow integration with Industry 4.0 platforms, enabling real-time monitoring and data-driven decision-making, which is particularly valuable in large-scale manufacturing.

Growth in Food and Beverage Applications

The food and beverage industry remains a key driver of the sleeving machine market, fueled by rising demand for packaged goods. Urbanization, growing middle-class populations, and increasing consumer preference for branded products are boosting the need for high-quality labeling solutions. Sleeving machines are critical for applying vibrant, durable labels that enhance shelf appeal and provide essential product information. Recent industry reports note a surge in demand for shrink sleeve labels in soft drinks and alcoholic beverages, where they offer 360-degree branding and tamper-evident features.

This sector’s growth is particularly strong in emerging markets, where rising disposable incomes are driving consumption of packaged foods. Sleeving machines are evolving to meet these demands, with manufacturers developing high-speed models capable of handling large production volumes without compromising quality. These machines are also designed to comply with stringent food safety regulations, ensuring labels are applied hygienically and securely.

Strategic Partnerships and Market Expansion

Strategic alliances are playing a pivotal role in expanding the sleeving machine market. In 2025, manufacturers are forming partnerships to enhance distribution networks and penetrate new regions. For example, collaborations between equipment suppliers and packaging material providers are streamlining supply chains, ensuring seamless integration of sleeving machines with compatible labels. These partnerships are critical for addressing regional variations in packaging standards and consumer preferences.

Recent industry developments also highlight mergers and acquisitions aimed at diversifying product portfolios. Leading players are acquiring smaller firms with specialized sleeving technologies, such as those focused on eco-friendly materials or high-speed applications. These strategic moves are strengthening market positions and enabling companies to offer comprehensive packaging solutions, particularly in high-growth regions like Asia-Pacific.

Regulatory and Environmental Considerations

Regulatory frameworks are shaping the sleeving machine market, particularly in developed regions where environmental compliance is stringent. Governments are imposing stricter regulations on packaging waste, pushing manufacturers to adopt machines that support sustainable materials. In Europe, for instance, new directives require packaging to be recyclable or compostable, driving demand for sleeving machines that can handle these materials efficiently.

Safety standards are also influencing machine design. Flame-retardant sleeves, increasingly used in industries like pharmaceuticals and cosmetics, require machines with precise heat control to ensure safe application. Manufacturers are responding by developing systems with advanced safety features, such as automated shut-off mechanisms and temperature regulation, to comply with global standards.

Regional Market Dynamics

The Asia-Pacific region is a key growth hub for the sleeving machine market, driven by rapid industrialization and rising consumer demand in countries like China and India. China’s household sewing machine market, while distinct, reflects similar trends in automation and consumer goods production, indicating a broader manufacturing boom that benefits sleeving machines. North America and Europe remain significant markets, with established players investing in R&D to maintain competitive edges.

Emerging markets are seeing increased adoption of sleeving machines due to growing e-commerce and retail sectors. However, challenges like high initial costs and the need for skilled technicians can hinder market penetration in less developed regions. Manufacturers are addressing these barriers by offering modular, cost-effective machines and training programs to support local workforces.

Competitive Landscape and Challenges

The sleeving machine market is highly competitive, with key players like Krones AG, Sacmi, and Fuji Seal International leading innovation. These companies are focusing on R&D to develop machines with enhanced speed, precision, and sustainability. Smaller players are carving out niches by offering affordable solutions tailored to specific industries, such as cosmetics or pharmaceuticals.

Challenges include the high cost of advanced machines, which can deter small and medium-sized enterprises. Additionally, the need for continuous workforce training to operate complex systems poses operational challenges. Supply chain disruptions, potentially exacerbated by global trade dynamics, could also impact the availability of machine components and materials.

Alignment with Global Trends

The sleeving machine market aligns with broader trends in automation and sustainability. The integration of AI and IoT technologies is transforming manufacturing, enabling predictive maintenance and real-time optimization. The focus on sustainable packaging reflects consumer and regulatory demands for eco-friendly solutions, positioning sleeving machines as critical tools in modern supply chains. Additionally, the rise of e-commerce is driving demand for visually appealing, durable packaging, further boosting the market.

Conclusion

In 2025, the sleeving machine market is thriving due to technological advancements, sustainability demands, and strong growth in the food and beverage sector. Innovations like AI integration and digital twin technology are enhancing efficiency, while strategic partnerships are expanding market access. Despite challenges like high costs and regulatory compliance, the market’s alignment with global trends in automation and eco-friendly packaging ensures its resilience. As industries prioritize efficiency and sustainability, sleeving machines will remain essential for delivering high-quality, environmentally conscious packaging solutions.

Write a comment ...